Tips for Proper Maintenance and Care of Pneumatic Blowers

Pneumatic blowers are indispensable tools in many industries, offering efficient and reliable solutions for moving air and other gases. From manufacturing plants to wastewater treatment facilities, these devices play a crucial role in ensuring smooth operations. However, like any machinery, pneumatic blowers require proper maintenance and care to ensure optimal performance and longevity. Whether you’re using pneumatic blowers in Midlothian, TX, or anywhere else, adhering to a comprehensive maintenance routine can save time, money, and resources in the long run.

Understanding Pneumatic Blowers

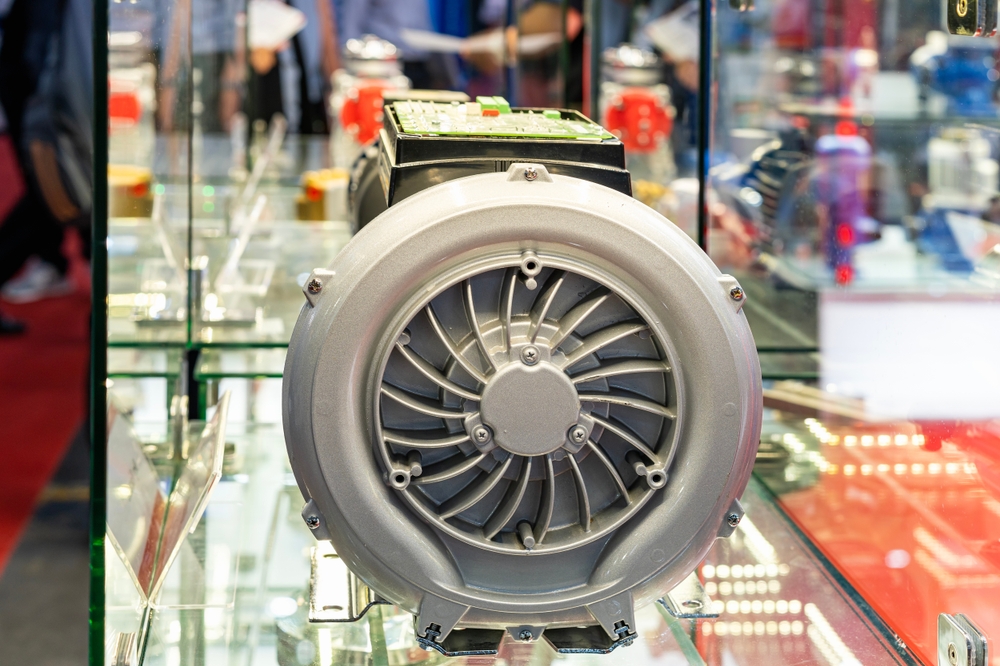

What Are Pneumatic Blowers?

Pneumatic blowers are mechanical devices designed to generate airflow or gas movement. They are used in various applications, such as aeration in wastewater treatment, material handling, and industrial vacuum systems. These blowers work by drawing air into the system and then expelling it at high pressure, making them versatile and highly effective in industrial settings.

Types of Pneumatic Blowers

- Positive Displacement Blowers: These operate by trapping air in a chamber and forcing it out through the discharge port.

- Centrifugal Blowers: These use a rotating impeller to accelerate air outward, creating airflow.

- Regenerative Blowers: These use non-contact rotating blades to create continuous airflow.

Knowing the type of blower you use is critical for implementing the appropriate maintenance strategies.

Importance of Regular Maintenance

Proper maintenance of pneumatic blowers ensures their efficiency, reliability, and longevity. Neglecting maintenance can lead to reduced performance, higher energy costs, and unexpected breakdowns.

Benefits of Regular Maintenance

- Improved Efficiency: A well-maintained blower operates at peak efficiency, consuming less energy and reducing operational costs.

- Extended Lifespan: Regular care minimizes wear and tear, extending the life of the blower.

- Reduced Downtime: Preventative maintenance helps avoid unexpected failures, keeping operations running smoothly.

- Enhanced Safety: Properly functioning blowers reduce the risk of accidents and malfunctions.

Key Maintenance Tips for Pneumatic Blowers

Establish a Maintenance Schedule

Creating a regular maintenance schedule is essential. Depending on the blower’s usage and environment, tasks may need to be performed daily, weekly, monthly, or annually.

Inspect for Wear and Tear

Frequent inspections help identify signs of wear and tear. Check components such as belts, seals, and bearings for damage. Replace any worn parts promptly to prevent further damage.

Keep the Blower Clean

Dust and debris can accumulate on the blower, reducing its efficiency and potentially causing overheating. Clean the exterior and interior parts regularly to ensure unrestricted airflow.

Lubricate Moving Parts

Lubrication reduces friction, minimizing wear and ensuring smooth operation. Use manufacturer-recommended lubricants and follow the suggested lubrication intervals.

Monitor Air Filters

Air filters prevent contaminants from entering the blower system. Inspect and replace filters as needed to maintain optimal airflow and prevent damage to internal components.

Check and Tighten Connections

Loose connections can cause air leaks, reducing the blower’s efficiency. Regularly check and tighten all bolts, screws, and fittings.

Measure Performance Metrics

Use monitoring equipment to track key performance metrics, such as airflow rate, pressure, and temperature. Significant deviations from standard values may indicate underlying issues.

Troubleshooting Common Issues

Even with regular maintenance, pneumatic blowers can encounter problems. Understanding common issues and their solutions can help you address them promptly.

Excessive Noise

- Cause: Worn bearings, loose components, or debris in the system.

- Solution: Inspect and replace bearings, tighten loose parts, and clean the blower.

Reduced Airflow

- Cause: Clogged filters, damaged impellers, or air leaks.

- Solution: Replace filters, repair or replace impellers, and seal leaks.

Overheating

- Cause: Poor ventilation, excessive friction, or overloading.

- Solution: Ensure proper ventilation, lubricate moving parts, and reduce the workload on the blower.

Best Practices for Longevity

Follow Manufacturer Guidelines

Always adhere to the manufacturer’s recommendations for maintenance and operation. This includes using the specified lubricants, replacement parts, and cleaning methods.

Train Operators

Ensure that all personnel operating the pneumatic blowers are trained in proper usage and maintenance procedures. Educated operators are less likely to misuse equipment or overlook maintenance needs.

Use Quality Replacement Parts

When replacing components, use high-quality parts that meet the manufacturer’s specifications. Inferior parts can compromise the blower’s performance and safety.

Keep a Maintenance Log

Documenting all maintenance activities provides a valuable record of the blower’s history. This log can help identify patterns, plan future maintenance, and provide evidence of proper care for warranty claims.

Specialized Maintenance Tips for Pneumatic Blowers in Midlothian, TX

Environmental factors in Midlothian, TX, such as temperature, humidity, and air quality, can impact the maintenance requirements of pneumatic blowers.

Consider Local Climate

- High Temperatures: Use heat-resistant lubricants and ensure adequate cooling.

- Humidity: Protect the blower from moisture, which can lead to rust and electrical issues.

Address Dust and Debris

Industrial environments in Midlothian, TX, may have higher levels of dust. Regularly inspect and clean the blower to prevent clogging and wear.

Partner with Local Experts

Collaborating with local service providers familiar with pneumatic blowers in Midlothian, TX, can ensure access to specialized expertise and timely support.

Conclusion

Proper maintenance and care are crucial for the efficient and reliable operation of pneumatic blowers. By following a structured maintenance schedule, addressing common issues promptly, and adapting to local environmental factors, you can maximize the performance and lifespan of your equipment. Whether you’re managing pneumatic blowers in Midlothian, TX, or elsewhere, investing in maintenance is an investment in your operation’s success. With these tips, you can keep your pneumatic blowers running smoothly and efficiently for years to come.

Contact Us Today

Here at Kerley & Sears Inc., we understand the importance of staying ahead with advanced maintenance solutions. As a family-owned business with over 50 years of experience in the sales, service, and repair of pneumatic tools and industrial vacuum parts, we are committed to providing you with the highest level of expertise and customer service. Whether you need reliable repairs, expert advice, or a free estimate, our dedicated team is here to help. Contact us today to discover how we can support your business with our top-quality products and services.