Top 10 Most Commonly Replaced Pneumatic Trailer Parts

Maintaining a pneumatic trailer in optimal condition is crucial for ensuring efficient operation and minimizing downtime. Pneumatic trailers, commonly used to transport dry bulk materials such as cement, sand, or grains, rely on several key components working in unison. Over time, wear and tear, exposure to harsh conditions, and regular use necessitate the replacement of certain parts. Whether you’re seeking pneumatic trailer parts in Mansfield TX or considering trailer repair for pneumatic systems in Mansfield TX, understanding the most commonly replaced components can help you stay ahead of potential issues.

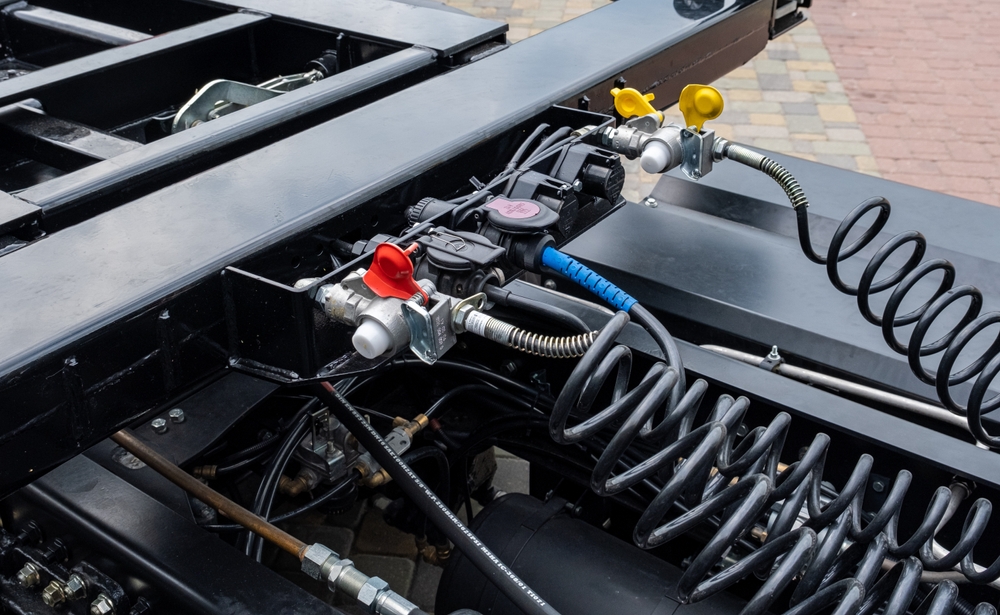

Pneumatic Valves: The Heart of Airflow Control

Pneumatic valves play an essential role in regulating the flow of air within a pneumatic trailer’s system. These valves control the pressurization and release of air, ensuring that materials are efficiently loaded and unloaded. Over time, valves can develop leaks, become clogged with debris, or suffer from internal wear due to constant cycling. When this happens, it’s imperative to replace the faulty valves promptly to maintain optimal performance. Regular inspections and timely replacements can prevent extended downtimes and ensure that your trailer’s pneumatic systems remain reliable.

For operators in Mansfield TX, sourcing high-quality pneumatic trailer parts locally can make a significant difference. Trusted suppliers in the area offer durable valve options to suit a range of trailer models, helping businesses maintain smooth operations.

Hoses and Tubing: Vital Pathways for Airflow

Hoses and tubing are integral to the pneumatic system, as they transport pressurized air to various components. Given their exposure to vibration, temperature fluctuations, and constant airflow, hoses and tubing are prone to wear, cracks, and punctures. Even a small leak in these pathways can reduce efficiency and lead to increased operational costs.

Replacing worn-out hoses and tubing is one of the most common trailer repair tasks for pneumatic systems in Mansfield TX. To avoid unexpected breakdowns, it’s advisable to inspect hoses and tubing regularly for signs of damage, such as visible cracks, bulges, or reduced airflow capacity. Investing in high-quality replacement parts ensures long-lasting performance and minimizes future maintenance needs.

Gaskets and Seals: Ensuring Leak-Free Operation

Gaskets and seals are critical components in pneumatic trailers, as they provide airtight connections between various parts of the system. Over time, exposure to high-pressure air and environmental elements can cause gaskets and seals to deteriorate, leading to leaks. A compromised seal not only reduces system efficiency but can also pose safety risks if materials escape during transport.

Operators often encounter issues with worn gaskets during routine maintenance or inspections. Fortunately, sourcing replacement gaskets and seals from reputable suppliers of pneumatic trailer parts in Mansfield TX is straightforward. Keeping spare gaskets on hand can also be a smart strategy for minimizing downtime during emergency repairs.

Air Compressors: The Powerhouse of the Pneumatic System

The air compressor is undoubtedly one of the most vital components of a pneumatic trailer. It generates the pressurized air needed to move materials through the system. However, compressors are also subject to significant strain, as they operate under high pressures and temperatures. Common issues include worn-out belts, damaged bearings, and reduced output efficiency.

When an air compressor begins to show signs of failure, such as unusual noises, overheating, or reduced airflow, immediate attention is required. Replacement compressors or repair kits can be sourced from providers specializing in trailer repair for pneumatic systems in Mansfield TX. Regular maintenance, including oil changes and filter replacements, can help extend the life of this essential component.

Filters: Keeping the System Clean

Filters play a crucial role in maintaining the cleanliness of a pneumatic trailer’s system by preventing dirt, dust, and other contaminants from entering the air supply. Over time, filters can become clogged, restricting airflow and reducing system efficiency. Neglecting to replace dirty filters can lead to more severe issues, such as damage to other components or decreased loading and unloading speeds.

Replacing filters is a simple yet impactful maintenance task that can significantly improve a trailer’s performance. Operators in Mansfield TX can benefit from local availability of high-quality replacement filters designed to fit various trailer models. Regular filter changes not only enhance system efficiency but also contribute to lower maintenance costs in the long run.

Check Valves: Preventing Backflow

Check valves are essential for preventing the backflow of materials or air within the pneumatic system. These valves ensure that pressurized air flows in the intended direction, supporting efficient operation. Like other components, check valves can wear out over time due to constant pressure and exposure to materials being transported.

When a check valve fails, it can disrupt the entire pneumatic system, leading to operational inefficiencies and potential safety concerns. Regular inspections and timely replacements are crucial to maintaining system integrity. For those in need of replacement check valves, suppliers of pneumatic trailer parts in Mansfield TX offer a range of durable options to meet specific requirements.

Pressure Gauges: Monitoring System Performance

Pressure gauges provide critical information about the performance of a pneumatic trailer’s system. They allow operators to monitor air pressure levels and identify potential issues before they escalate. However, pressure gauges can become inaccurate over time due to wear or exposure to vibrations and harsh conditions.

Replacing faulty pressure gauges is essential for maintaining accurate system monitoring and ensuring safe operation. Mansfield TX offers access to reliable sources for high-quality gauges, making it easier for operators to keep their trailers in peak condition. Regular calibration and replacement of gauges can also contribute to improved operational efficiency.

Butterfly Valves: Facilitating Material Flow

Butterfly valves are commonly used in pneumatic trailers to regulate the flow of materials during loading and unloading. These valves are designed to withstand high-pressure environments and frequent use, but they are not immune to wear and tear. Over time, the seals and moving parts within butterfly valves can degrade, leading to leaks or reduced functionality.

Replacing worn-out butterfly valves ensures that materials are transferred efficiently and without delays. Operators in need of reliable replacement parts can turn to local suppliers specializing in trailer repair for pneumatic systems in Mansfield TX. Regular lubrication and maintenance of these valves can also help extend their lifespan.

Bearings: Supporting Smooth Operation

Bearings are essential for the smooth operation of various moving parts within a pneumatic trailer’s system. They reduce friction and support the rotation of components such as motors, compressors, and valves. However, bearings are susceptible to wear due to constant motion and exposure to dust and debris.

When bearings begin to fail, operators may notice increased noise, vibration, or reduced system efficiency. Timely replacement of worn bearings is critical to preventing further damage to adjacent components. Fortunately, Mansfield TX offers access to a range of high-quality bearings designed to meet the demands of pneumatic trailers.

Manifold Systems: Distributing Airflow

The manifold system is responsible for distributing pressurized air throughout the pneumatic trailer’s system. Over time, manifolds can develop cracks, leaks, or blockages that compromise their functionality. A damaged manifold can disrupt the entire system, leading to inefficiencies and potential downtime.

Replacing or repairing manifold systems requires expertise and access to quality replacement parts. For operators in Mansfield TX, partnering with experienced professionals in trailer repair for pneumatic systems can ensure that manifold issues are resolved effectively. Regular inspections and cleaning of the manifold system can also help prevent premature wear.

Conclusion

By understanding the most commonly replaced pneumatic trailer parts and prioritizing regular maintenance, operators can keep their trailers running efficiently and avoid costly repairs. Whether you’re sourcing pneumatic trailer parts in Mansfield TX or seeking expert trailer repair for pneumatic systems, staying proactive can make all the difference in ensuring reliable and long-lasting performance.

Contact Us Today

Here at Kerley & Sears Inc., we understand the importance of staying ahead with advanced maintenance solutions. As a family-owned business with over 50 years of experience in the sales, service, and repair of pneumatic tools and industrial vacuum parts, we are committed to providing you with the highest level of expertise and customer service. Whether you need reliable repairs, expert advice, or a free estimate, our dedicated team is here to help. Contact us today to discover how we can support your business with our top-quality products and services.